In the competitive world of packaging, businesses are constantly seeking printing solutions that combine efficiency, versatility, and cost-effectiveness. One of the most reliable technologies that has stood the test of time is flexographic printing. Flexo printing machines have become the preferred choice for industries working with kraft paper and corrugated packaging, offering the perfect balance between speed, quality, and adaptability.

Flexibility on Various Materials

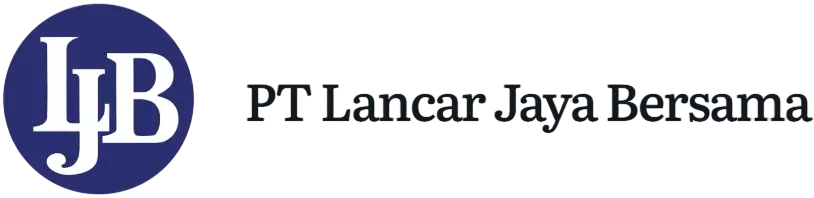

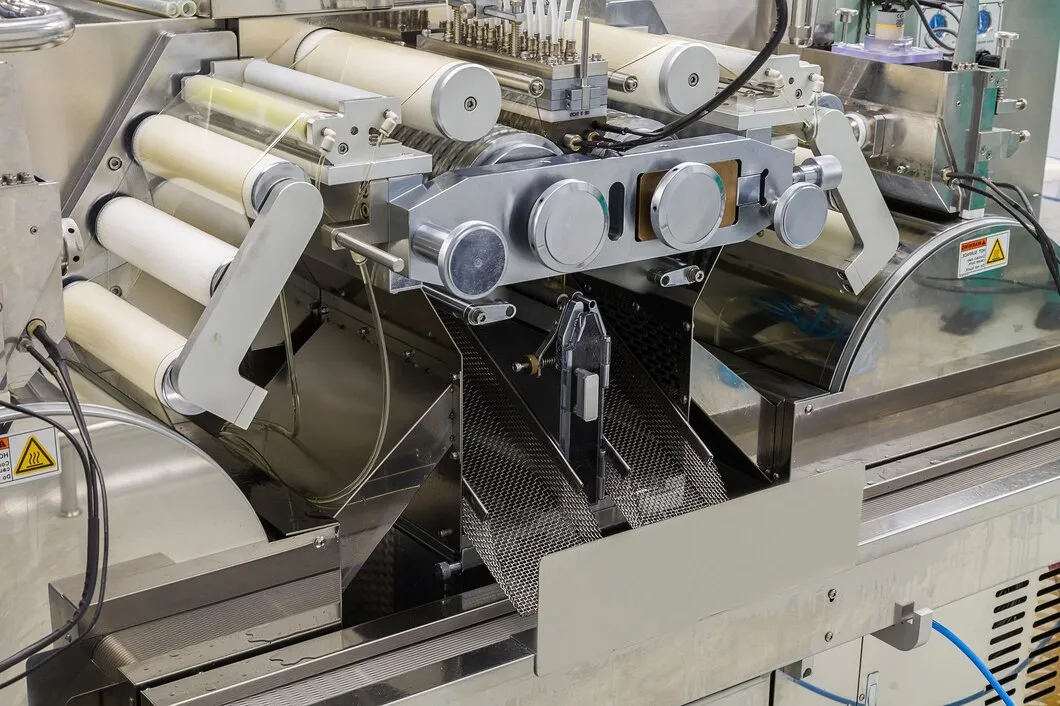

Flexo printing machines are designed to handle a wide range of substrates. From lightweight kraft paper to heavy corrugated board, flexo presses deliver consistent results without sacrificing speed. This adaptability makes them ideal for businesses that need to meet diverse packaging requirements while maintaining high production output.

Cost-Effective and Efficient

Compared to other printing methods, flexo machines are known for their lower operational costs. The quick setup process and ability to use water-based inks reduce overall expenses, making them highly economical for large-volume packaging runs. For businesses working on tight margins, this efficiency is a significant advantage.

High Printing Quality

Modern flexo printing machines have evolved to deliver sharper details, vibrant colors, and smooth finishes. Advances in plate technology and ink formulations ensure that kraft paper and corrugated surfaces can achieve excellent print clarity. This allows brands to maintain high-quality visuals that elevate their packaging appeal.

Eco-Friendly Printing Solution

Sustainability has become a critical focus in packaging. Flexo printing supports this demand by using eco-friendly inks and producing less waste compared to traditional methods. The ability to print on recyclable materials such as kraft paper also makes flexo an environmentally responsible choice for companies committed to green practices.

Scalability for Growing Businesses

As customer demands increase, businesses need printing solutions that can scale quickly. Flexo printing machines are built for high-speed operation, making them capable of handling both small and large production runs efficiently. This scalability ensures companies can adapt to market growth without the need for frequent machine upgrades.

Conclusion

Choosing flexo printing machines for kraft paper and corrugated packaging is a smart investment for businesses aiming to combine quality, efficiency, and sustainability. With the ability to deliver high-speed production, cost savings, and environmentally friendly results, flexo printing continues to be the most practical and future-proof choice in the packaging industry.